This articles explores the topic of one way slab and two way slab, how they work structurally and how they differ from eachother.

Introduction

As you probably know, one of the most important structural elements in buildings are slabs. They are typically horizontal and flat surfaces made of concrete or other materials. When it comes to concrete slabs, steel-reinforced slabs are used more often for ceilings and floors. The thickness of a concrete slab is usually around 100-500mm. Some builders also use thin slabs for exterior paving. For the construction of ground floors and foundations, thick concrete slabs are typically used.

Structurally speaking, slabs can be categorized in two types, which we will focus on in this article. Let’s have a look at them and identify differences among them.

One-Way Slab

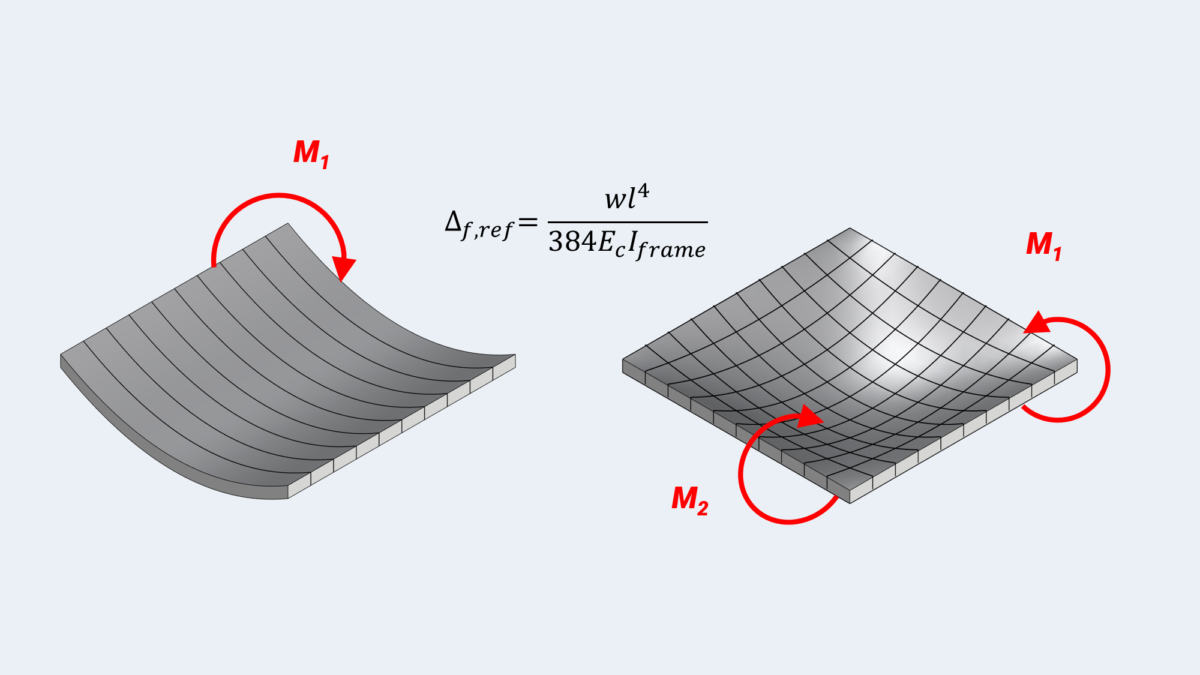

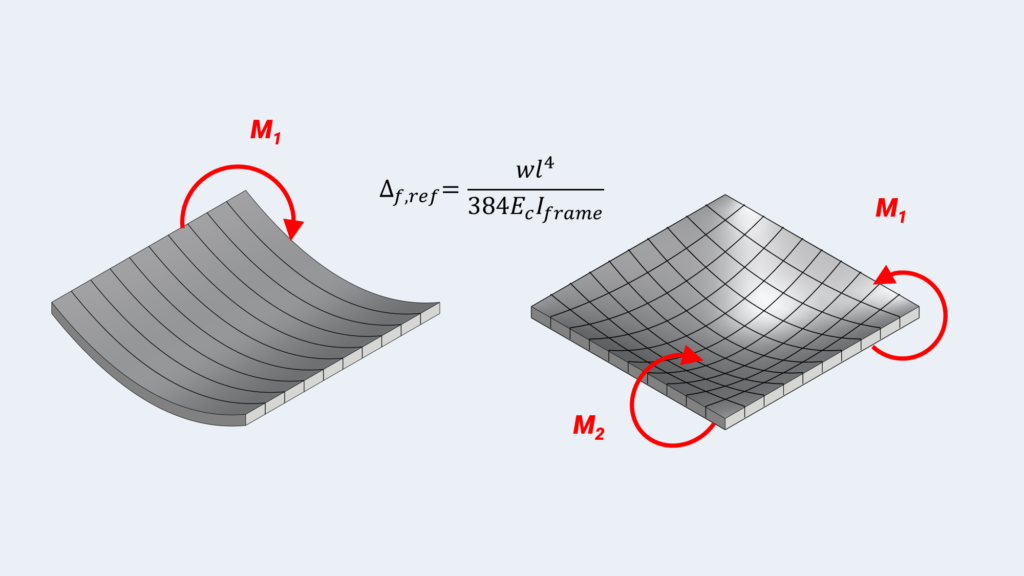

The one-way slab has reinforcements which help resisting bending moments from bending along the slab’s long direction. One-way slabs deforms under load into a cylindrical surfaces. The direction that is normal to support on opposite sides of the rectangle is the structural action present in the one-way slab. The designs of the one-way slab include ribbed slabs and corrugated slabs.

In case of one-way slab, if we increase the beams width to depth ratio, and increase the percentage of steel, perpendicular to the direction of bending, then one-way slab will be more economical and will be stronger than two way slab. When we apply the load, a one-way slab bends into a surface that is in the shape of a disc rather than cylindrical.

It means that if at a point, the slab is curved in both of the principal directions, the curvature is proportional to bending moments which also exist in both of the directions. This is a distinguishing factor related to the one-way slab which makes it different from the two-way slab. In further discussion, the focus will be on the two-way slab and its distinguishing features.

Did you like this post? Sign up and we’ll send you more awesome posts like this every month.

Two-way Slab

This type of slab has a reinforcement that resists moments in both directions. One of the most important aspects of two-way slabs is the ratio between two horizontal spans. If ly:lx < 2, where lx is shorter dimension and ly is longer slabs dimension, then it is considered as a two-way slab. Moments from both of the directions are important for design development. So, it is quite evident from the above discussion that if the axial ratio is more than 2, it requires a two-way slab.

To resist the moments, the slab is reinforced in each of the two directions. Usually, two bars layers are used perpendicularly to reinforce the slab. The slab must be designed for taking a proportionate amount of load in every direction.

Different types of reinforced concrete are important in the two-way slab that include:

- Slabs supported by beams or walls from all sides,

- Those which get support directly over columns are the flat plates.

- Such slab which is without the beam, but gets support from the drop panel, is the flat slab.

Some of the choices in two-way slabs is cut-off, such as straight bars and bent bars. On industrial scale, bar fabrication favors the straight bars because its manufacturing is economic. It is important that the reinforcement spacing should not exceed 2 times the thickness of slab, because it will result in occurrence of flexural cracks.

Difference between the one-way and two-way slab

- In a one-way slab, the main source of load transmission is the longer direction. On the other hand, in the two-way slab, the shorter and larger sides are the main source for transmission of load. In a one-way slab, the bending moment occurs in a singular direction, while in a two-way slab it occurs in both directions.

- Another important difference is the content of steel in both types of slabs. One-way slabs have less content of steel than the two-way slab, as it has steel in one direction.

- The two-way slab has main reinforcement bars in both directions. On the other hand in the one-way slab, the reinforcement bars are in a parallel direction to the shorter side.

- The two-way slab is applicable for panel sizes of 6m x6 m (Mahajan, 2020). However, a one-way slab is economical for a 3.5m panel. In this way, the application of both of the slabs is different.

- We can notice that in the one-way slab, the type of deflection is a cylinder and in the two-way slab, it has a slight curve. In this way, the two of the slabs and their deflections are different from each other. It is an effective method for evaluating the type of slab by checking the type of deflection in that slab. It gives an idea about the nature of the slab.

- We put less steel in the one-way slab, due to which results in increasing its thickness. On contrary, in the two-way slab, the steel is more, so it results in increasing its depth. In this way, there is a difference between the thicknesses of both slabs.

Some application of the one-way slab are in Cantilever slab and verandahs. Similarly, the applications of the two-way slab are that they are in use for creative floorings, which include decorative floors or multi-story buildings. In this way, from the examples, we can determine the difference between the functions of one-way and two-way slabs

Conclusion

It is quite evident from the discussion that there is a huge difference between one-way and two-way slabs. Both of these slabs have their applications based on their characteristics. It is important to conduct a thorough analysis of requirements before deciding accordingly. It is necessary to identify the main aspects before selecting the right type of slab, including loading conditions. One of the best ways to calculate the loads from two-way slabs is Tribby3d.